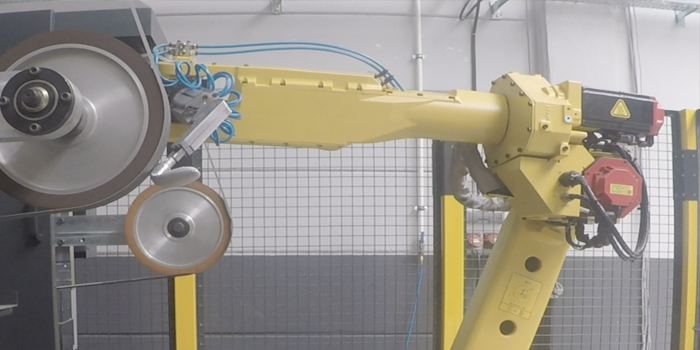

Robotic Chair Base Polishing

ROBOTIC POLISHING

Automated polishing is an effective way to increase throughput and part quality.

As with most automation tasks, some key indicators indicate that automation may

be beneficial.

Those include things like having a current bottleneck at the finishing stage,

requiring more

consistent performance, and a need to increase safety around the polishing line.

Polishing robots typically produce at a higher rate than human operators.

This can speed up the finishing process which can remove the bottleneck.

In addition, since robots follow programmed steps, they offer a higher level of

consistency

than human operators. Finally, if safety is a concern, relocating human

operators from a dangerous

task like polishing can help to reduce safety incidents.